Electrical control plays a vital role in automating, safeguarding, and optimizing industrial processes. These solutions help increase operational efficiency, ensure safety compliance, and enable smarter monitoring and management. Businesses in Indonesia and worldwide rely on modern control systems to maintain competitiveness, reduce costs, and improve productivity.

Table of Contents

ToggleUnderstanding Electrical Control and Its Importance

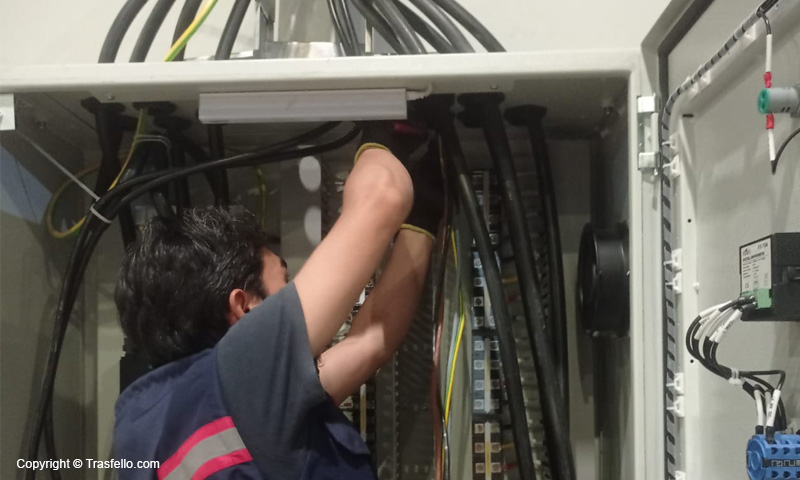

Electrical control refers to the use of devices and technology to manage and regulate electrical circuits automatically. Common components include relays, sensors, programmable logic controllers (PLCs), and control panels. These systems help minimize human error, enhance safety, and reduce operational costs. Proper design and integration of control systems ensure smooth workflows, scalable infrastructure, and the flexibility to adapt to evolving industry needs.

Key Components and Their Functions

To understand how these systems work, it’s useful to know the main components involved. Each plays an integral role in maintaining efficient, safe, and continuous operations.

| Component | Function | Industrial Application |

|---|---|---|

| Relays | Switch electrical signals on/off | Machine automation, safety shutdown |

| Sensors | Detect environmental changes | Temperature, pressure, motion sensing |

| Programmable Logic Controllers (PLCs) | Automate complex control tasks | Factory automation and monitoring |

| Motor Starters | Control motor operations | Pumps, compressors, fans |

| Control Panels | Central interface for system control | Process visualization and alerts |

Together, these components form a reliable system that supports modern industrial automation needs.

Types of Control Systems and Their Applications

Electrical control systems vary significantly in complexity and functionality. Each type offers unique advantages tailored to different operational requirements.

Understanding these options is crucial to choosing an appropriate system that balances efficiency, cost, and future scalability.

- Manual Control Systems: These rely on direct human operation with switches and buttons. They offer simplicity and are suitable for limited or straightforward tasks but lack automation benefits.

- Automatic Control Systems: Utilizes sensors and relays to perform tasks independently without constant human input. Ideal for repetitive or time-sensitive processes.

- Programmable Control Systems: Advanced systems programmed via software (PLCs) to provide customized, flexible control suited for complex manufacturing and Industry 4.0 integration.

Selecting the right system involves assessing operational demands and preparing for future upgrades.

Benefits of Implementing Electrical Control in Industry

The advantages of these solutions extend far beyond automation. They provide measurable improvements in productivity, safety, and costs.

Recognizing these benefits helps industries justify investments and optimize their operational strategies.

- Enhanced Efficiency: Automation reduces human error, increases throughput, and cuts downtime.

- Energy Conservation: Intelligent control systems optimize energy consumption, reducing utility costs.

- Safety and Compliance: Automated shutdown and monitoring prevent accidents and meet regulatory standards.

- Real-Time Performance Monitoring: Data-driven insights allow proactive maintenance and process improvements.

By leveraging these benefits, businesses can maintain a competitive edge and ensure long-term sustainability.

Read Also :

Discover the Power of Electrical Instrumentation in Industry Today

Industry Applications Highlight

Electrical control systems are indispensable across multiple sectors, each with its tailored needs and challenges.

These systems transform how industries operate, delivering improved performance and cost savings.

| Industry | Area of Use | Key Benefits |

|---|---|---|

| Manufacturing | Robotic assembly lines, CNC machines | Higher productivity and quality control |

| Energy Sector | Power substations, distribution networks | Increased uptime and fault detection |

| Transportation | Traffic signals, automated gates | Improved safety and traffic management |

| Water Treatment | Pump stations, purification plants | Efficient resource monitoring and usage |

These examples illustrate the wide-ranging impact of control systems on industrial innovation.

Emerging Trends and Innovations

The field of electrical control continues to evolve, integrating cutting-edge technology to meet modern demands.

Keeping abreast of these trends enables businesses to adopt future-ready solutions that enhance their operations.

- Internet of Things (IoT) Integration: Extends monitoring capabilities through cloud connectivity and remote management.

- Smart Controls: Artificial intelligence and machine learning optimize system responses for greater efficiency.

- Cybersecurity: Strengthens protection against digital threats to maintain operational integrity.

Incorporating these advancements ensures robust, adaptive control systems able to support evolving industrial challenges.

Choosing the Right Provider for Electrical Control Solutions

A critical factor in successful control system deployment is partnering with a reputable provider.

Key considerations include product certification, technical expertise, support services, and customization capabilities.

Trasfello stands out as a trusted official provider offering certified, industry-grade electrical control systems backed by expert consultation and local support. Many leading Indonesian companies rely on Trasfello for dependable, scalable solutions tailored to their unique business goals.

Practical Tips for Maintenance and Optimization

Maximizing the lifespan and performance of control systems requires proactive maintenance and staff training.

Effective practices help prevent downtime, ensure safety, and extend system usability.

- Regular inspections and preventive maintenance schedules.

- Comprehensive operator training on procedures and safety.

- Keeping software and firmware up-to-date.

- Planning for modular upgrades as operations grow.

Following these recommendations supports continuous efficiency and regulatory compliance.

Frequently Asked Questions

They automate complex processes, promoting efficiency, safety, and cost control.

Yes, programmable systems provide flexible configurations to fit unique workflows.

Offering certified products and local expert support, Trasfello guarantees reliable, scalable implementations.

Investing in robust electrical control solutions is foundational to modern industry success. With tailored systems from trusted providers like Trasfello, companies gain automation advantages, reduce risks, and improve resource management—all essential for thriving in today’s competitive industrial landscape.